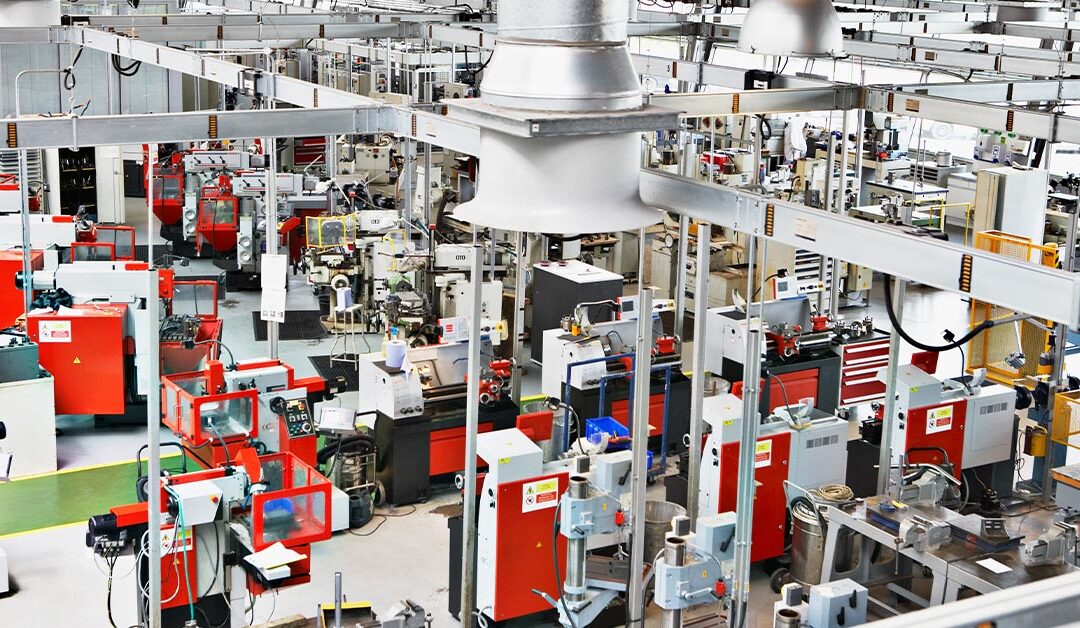

The rapid evolution of industrial manufacturing has brought forth a new era of real-time data, automation, and intelligent decision-making—an era fueled by the widespread adoption of smart sensors. These highly advanced sensing devices have become essential tools in optimizing production processes, improving precision, and ensuring consistent product quality across various industries. As manufacturing systems shift from traditional manual operations to interconnected, digitally driven environments, smart sensors provide the backbone of Industry 4.0 and the emerging Industry 5.0. Their role extends far beyond simple data collection; they enable predictive insights, self-adjusting systems, and fully automated workflows. As global manufacturers compete for efficiency, sustainability, and innovation, the dependence on smart sensors continues to grow. This article explores how smart sensors are transforming industrial manufacturing, why they are becoming indispensable, and how businesses benefit from integrating them into modern production environments.

One of the key reasons manufacturers rely heavily on smart sensors is their ability to provide real-time, accurate, and actionable data. Traditional sensors are limited to basic readings such as temperature, pressure, or speed, but smart sensors combine multiple functions—including data processing, condition monitoring, and communication—in a single integrated device. These sensors can detect subtle changes in machinery performance, environmental conditions, and production variables that would otherwise go unnoticed. For instance, vibration sensors detect early signs of bearing wear in rotating equipment, while temperature and humidity sensors ensure sensitive materials are handled under optimal conditions. With the help of built-in microprocessors and communication modules, smart sensors can send this data directly to control systems, cloud platforms, or supervisory dashboards. This seamless data flow allows manufacturers to monitor performance continuously, make informed decisions quickly, and resolve issues before they escalate into major operational disruptions. As manufacturing becomes increasingly precise and automated, real-time data from smart sensors is fundamental to maintaining process stability and productivity.

Another major factor driving the reliance on smart sensors is their role in enabling predictive maintenance—a transformative shift from the traditional reactive and scheduled maintenance models. In the past, manufacturers relied on manual inspections or fixed maintenance schedules, often resulting in unnecessary downtime or unexpected machine failures. Smart sensors eliminate these inefficiencies by providing ongoing condition monitoring of machinery. They detect abnormalities such as excessive vibration, temperature spikes, unusual energy consumption, or lubrication issues long before equipment reaches a critical failure point. By analyzing sensor data, manufacturers can predict when a machine requires maintenance, schedule interventions at optimal times, and avoid costly unplanned downtime. This predictive approach extends the lifespan of equipment, reduces repair costs, and enhances operational reliability. As industries continue to scale up production and automate complex systems, predictive maintenance powered by smart sensors becomes not only beneficial but essential for uninterrupted operations.

Smart sensors also play a pivotal role in improving product quality and process accuracy. In high-precision manufacturing sectors—such as automotive, aerospace, medical device production, and electronics—even the smallest deviation from specifications can compromise safety, performance, or functionality. Smart sensors integrated into CNC machines, robotic systems, and assembly lines continuously track variables like dimensional tolerances, tool wear, surface finish quality, and material characteristics. If the sensor detects a deviation, the system can automatically adjust machining parameters or alert operators to take corrective action. This automated feedback loop significantly reduces defect rates, improves product uniformity, and enhances overall manufacturing output. Additionally, smart sensors enable traceability, documenting critical parameters throughout the production process. This is particularly important for industries that must meet stringent regulatory standards and quality certifications. By ensuring that every component is manufactured under controlled and verified conditions, smart sensors strengthen quality assurance and help manufacturers maintain a competitive edge.

Energy efficiency and sustainability are becoming increasingly important priorities for modern manufacturing plants, and smart sensors play a vital role in helping companies meet environmental and cost-reduction goals. These sensors monitor energy consumption, identify inefficiencies, and optimize the performance of machines, HVAC systems, lighting, and industrial processes. For example, energy sensors can detect when machines run idle or operate beyond safe thresholds, prompting automatic shutdowns or power adjustments. Smart flow sensors help regulate water usage in cooling systems, while gas and emission sensors ensure compliance with environmental standards. By enabling precise control of resources, smart sensors help manufacturers minimize waste, reduce operational costs, and cut carbon emissions. They also support the transition to greener production methods by providing the data required for sustainability reporting and certification. As global regulations tighten and consumers demand environmentally responsible manufacturing, smart sensors offer a practical and effective pathway to achieving sustainable operations.

Another significant reason for the growing dependence on smart sensors is their seamless integration with advanced technologies that define modern manufacturing ecosystems. Smart sensors act as the foundational layer for the Industrial Internet of Things (IIoT), enabling connected devices to communicate, analyze data, and respond autonomously. When combined with artificial intelligence, machine learning, robotics, and digital twins, smart sensors create powerful intelligent systems capable of optimizing entire production lines. Data collected from sensors is used to simulate real-world scenarios, improve machine learning models, or fine-tune robotic motions. In addition, smart sensors support remote monitoring and control, allowing engineers to oversee plant operations from anywhere. This capability proved especially valuable during global disruptions that limited physical presence on factory floors. As manufacturers continue to adopt hyper-automation and cyber-physical systems, smart sensors remain essential building blocks that enable advanced connectivity, efficiency, and scalability.

In conclusion, the growing dependence on smart sensors in industrial manufacturing reflects a fundamental shift toward intelligent, data-driven, and highly automated production environments. From enabling real-time monitoring and predictive maintenance to improving quality control, enhancing energy efficiency, and supporting the integration of next-generation technologies, smart sensors play an indispensable role in shaping the future of global manufacturing. Their ability to transform raw data into meaningful insights empowers manufacturers to achieve higher levels of precision, reliability, and operational excellence. As industries continue to evolve, smart sensors will remain at the forefront of innovation, driving continuous improvement and enabling companies to stay competitive in an increasingly complex and technology-driven world.